Whether you’re a beginner or a professional knife maker, having the right gas forge is essential for starting your bladesmithing journey. But with so many options available, it can be difficult to know which one is right for you.

To help make the decision easier, we’ve rounded up some of the best gas forges on the market that are perfect for making all types of knives.

In this blog post, we’ll take a look at multiple gas forges and explain what type of knife they’re good for. We’ll cover all their features, pros and cons, as well as a detailed buyer’s guide to help you find the right forge that will suit your needs.

Best Gas Forges for Knife Making

- Mr Volcano Hero 2 (Best Overall)

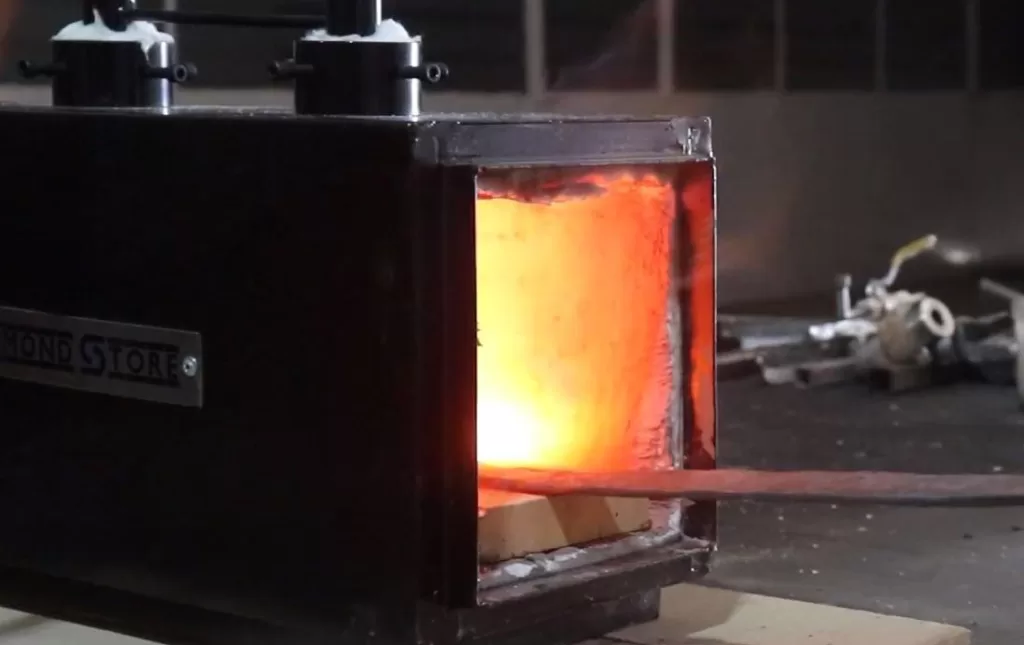

- Simond Store Single Burner (Best Single Burner)

- ATkrou GY200 (Best for Heat Treating)

- Simond Store Triple Burner (Best for Long Knives)

- Hell’s Forge Single Burner (Most Durable)

- Mr Volcano Hero (Best for Beginners)

Note: We chose these gas forges based on a variety of criteria, including price, features, and overall performance when it comes to making knives. After testing each forge we found that all of them worked great for knife making. But some had specific features which made them better suited to certain projects. Pick the one that fits your needs and get ready to create amazing pieces!

Mr Volcano Hero 2 (Best Overall)

I chose the Hero 2 gas forge by Mr Volcano as the best overall option because it is excellent value for money, has high-quality stainless steel construction, and has all the necessary features for making knives.

It has a dual burner design which allows it to heat up fast and evenly, making it more efficient than single-burner forges. The temperature control is very precise, allowing me to achieve consistent results every time I use it.

The portability of this forge is also great as it is light enough to be moved from one place to another. It also comes with a complete kit that includes all the necessary tools and accessories needed for knife-making, such as Superwool XTRA insulation. This makes it perfect for beginners and advanced bladesmiths alike.

Overall, I highly recommend the Mr Volcano Hero 2 if you’re looking for an affordable yet reliable forge for making all types of knives. The “Made in the USA” quality, portability, affordability, and performance make it one of the best overall options out there!

| Pros |

|---|

| Cons |

|---|

Simond Store Single Burner (Best Single Burner)

If you’re looking for a solid single-burner gas forge to make knives with, I would highly recommend this one by Simond Store. I chose it over other single-burner forges for its build quality and top-notch performance.

Being only 10″ in length allows it to reach forging temperatures in minutes, saving time and fuel. Of course, that does limit you to only being able to make smaller to mid-sized knives. But, anything larger than 10″ means you will need to look for at least a gas forge with 2 or more burners.

As far as its knife-making abilities, it has everything you need including a sturdy design, an easy-to-control regulator, and great insulation. It can also withstand temperatures of up to 2500°F, which is more than enough to forge most knife metals and even make your own Damascus.

Overall, this is an excellent gas forge if you just plan on making small knives and are constrained by space. You’ll always find a project and place suited for its size and quality performance. Simond Store forges are built to last and are great for all levels of bladesmiths.

| Pros |

|---|

| Cons |

|---|

ATkrou GY200 (Best Heat Control)

One of the most challenging parts of forging knives is thorough and even heat-treating. The GY200 forge by ATkrou addresses the delicate balance of proper heat distribution with several of its unique features.

Firstly, the burners are positioned closer to each other for even heat distribution. It also has side ventilation holes for better air circulation. In addition, it has a double-door design for faster heating and heat retention. It is also very portable, making it easy to take with you on the go.

Although the GY200 insulation is rated for temperatures up to 2600°F, I found it can get much hotter than that!

Overall, I highly recommend the ATkrou GY200 Propane Forge Kit if you’re looking for an efficient and reliable propane forge with excellent heat control. Not only does it provide even heating, but it can also achieve very high temperatures – perfect for knife-making!

| Pros |

|---|

| Cons |

|---|

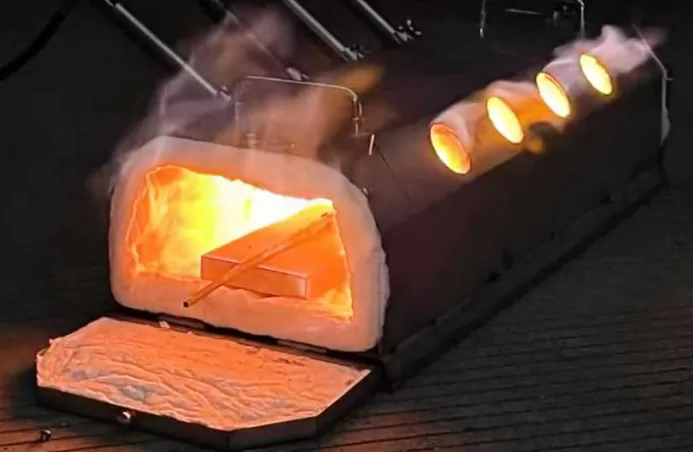

Simond Store Triple Burner (Best for Long Knives)

So far the forges I’ve mentioned were all great for making small to medium knives. But if you’re looking to make knives that are longer than 16″, you’ll need a gas forge with at least 3 burners.

Simond Store sent over their flagship triple burner forge and it’s by far one of the best forges I’ve ever used. Not only does it put out enough heat to forge longer knives, but also has a hinged door to help with heat treating.

The build quality is also top-notch and the insulation came pre-coated with a ceramic coating, which saved me from making a huge mess. The three burners are adjustable and can reach up to 2600°F, which is more than enough for most knife forging projects.

Overall, you get what’s advertised with Simond Store. If you have the space and budget for a triple-burner forge, I highly recommend this one! It will be an invaluable asset in your shop for making longer knives.

| Pros |

|---|

| Cons |

|---|

Hell’s Forge Single Burner (Most Durable)

If you’re looking for durability and don’t mind spending a few extra bucks for high-quality tools, then Hell’s Forge is perfect for you!

The single-burner gas forge is incredibly durable and has shown the least amount of wear compared to any other propane forge I’ve used to make knives. Although it’s only rated for temperatures of 2300°F, I’ve taken it to much higher temperatures with no signs of wear or tear.

It comes with a small container of “HELLCOTE 3000” refractory cement, which was more than enough for this tiny forge. Mine also came with a custom “Thank You” letter from the owner of the company, which added a personal touch that you won’t find with any other company.

I’ve literally taken this small gas forge to “Hell and Back” and it hasn’t let me down yet. If you’re looking for the Cadillac of forges, Hell’s Forge is definitely worth the money!

| Pros |

|---|

| Cons |

|---|

Mr Volcano Hero (Best for Beginners)

Most beginner knife makers want a cheap gas forge that won’t break after a few uses. They also want a forge that will last throughout their bladesmithing journey and not have to suffer from buyer’s remorse after gaining some experience.

That’s why I chose the Hero by Mr Volcano as the perfect forge for hobbyists and beginners!

The forge is Made in the USA and comes with all the accessories you need to start making knives from day 1. It has a temperature rating of up to 2600°F if you plan on forge welding different types of metals.

The body is stainless steel and the burner is easy to operate. Best of all, you get all this for under $100!

So, if you’re still looking for a reliable, affordable, and durable gas forge to get your knife-making project going, the Hero is perfect for you.

| Pros |

|---|

| Cons |

|---|

Buyer’s Guide to Gas Forges for Knife Making

When it comes to narrowing down the best gas forge for knife making, there are a few key features you should consider.

Below we’ll discuss some of the most important factors to help you find the perfect forge for your needs.

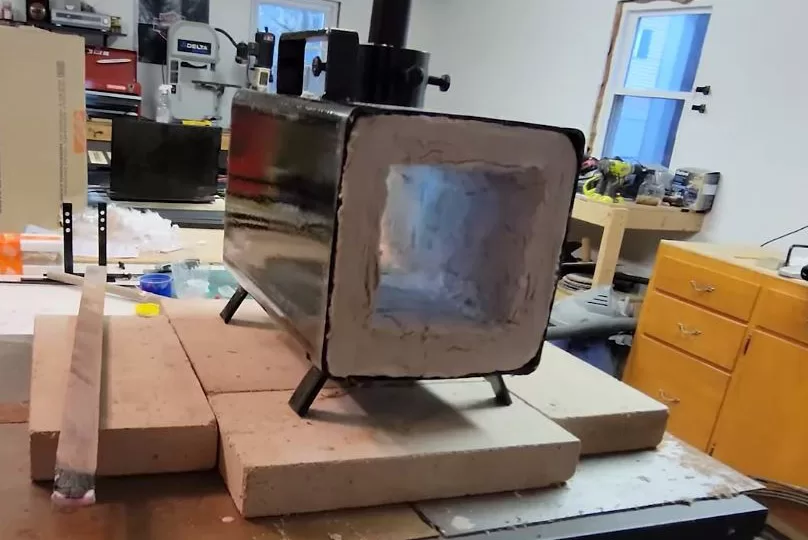

Forge Shape and Size: The shape and size of your forge will depend on the type of knives you plan to make. Smaller forges are better suited for making smaller blades, while larger ones can accommodate longer, thicker blades.

As a beginner knife maker, you might think bigger is better. But that’s not always the case. Bigger forges will require additional space in your shop, take longer to reach forging temperatures, and use up more fuel.

So, before you go out and purchase a large forge, make sure it’s the right size for your projects.

Fuel Type: When it comes to selecting a fuel type, you’ll want to consider two things: how much heat you need and what type of gas is available in your area. Propane gas is most commonly used for knife making because of its convenience and availability. A 20lb tank will typically last for 35-40 hours of use. Natural gas is also an option if you expect to use your forge regularly. However, you will most likely need a professional installer and additional plumbing.

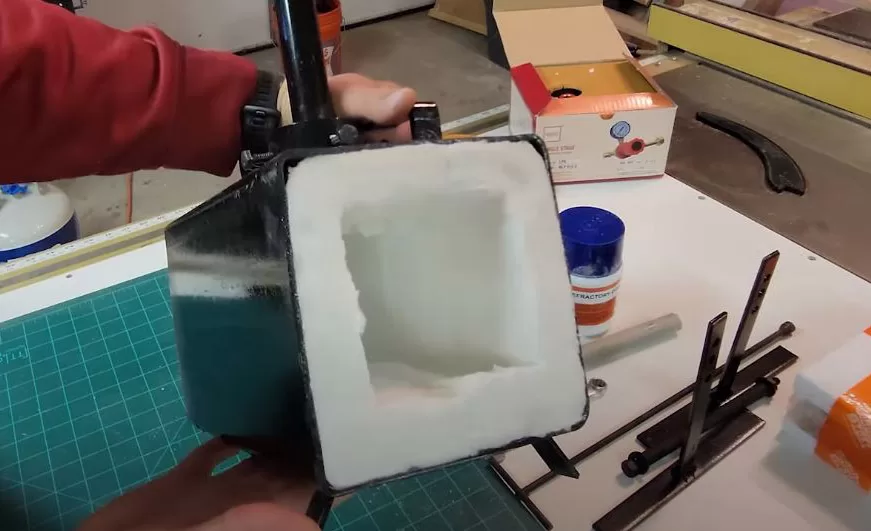

Insulation: A forge’s insulation is what keeps the heat inside and prevents it from escaping. The most common type of insulation used in gas forges is fire brick, a refractory material that can withstand high temperatures without deteriorating.

Other types of insulation materials include castable refractories, insulating fibers, ceramic linings, and refractory cement. Each material has its own set of pros and cons, so it’s important to do some research before selecting the best one for your application.

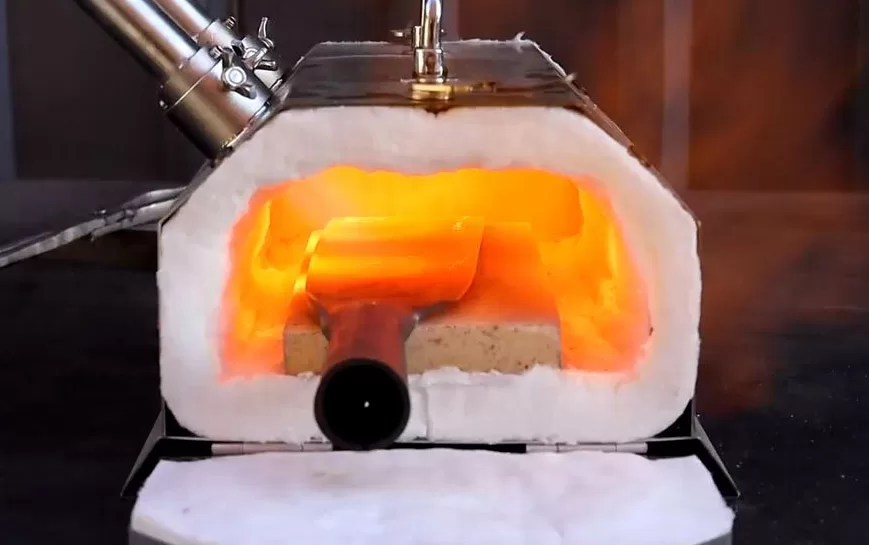

Burner and Regulator: Gas forges typically have between one and four burners, depending on their size. The number of burners you use will depend on the size of your forge and the type of blades you plan to make.

The burner is connected to a regulator that allows you to adjust the pressure and flow rate for optimal heat output. This is important for achieving accurate temperatures during forging.

The general rule of thumb is the more burners you have, the more heat output you will get and the more fuel you will use.

Portability: Even if you don’t intend to travel with your gas forge, portability is still an important factor to consider. Some forges are designed to be assembled and disassembled quickly, giving you the flexibility to move them from one workspace to another.

Others feature heavy-duty frames that allow for a more permanent setup and can support larger knife-making projects.

Heating Capacity: The heating capacity of a gas forge is typically measured in British Thermal Units (BTUs) per hour. The higher the BTU, the more heat your forge can generate.

For making knives, you will need a forge that can reach temperatures of at least 2,000°F (1,093°C). This will allow you to do forge welding and possibly even dabble with making Damascus steel.

Heat Distribution: To ensure even heat distribution, you’ll need to make sure your forge has proper ventilation. This will allow the hot gases to escape, keeping the temperature inside consistent.

Most gas forges come with built-in fans or vents that help keep the heat contained and can be adjusted depending on your needs.

Durability: A well-built gas forge can last for decades. The key is to select one that’s made of high-quality materials and has been designed to withstand the rigors of knife making.

Look for a forge with a sturdy frame, heavy-duty insulation, and reliable burners and regulators. This will help ensure it can handle even the toughest projects without breaking down.

Budget: Last but not least, you’ll need to consider your budget when selecting a gas forge. Forges can range in price from less than $100 to over $1,000! So it’s important to set a budget and do some research to find the best option for your needs.

Benefits of a Gas Forge for Knife Making

Using a gas forge has a number of benefits, especially when compared to traditional coal forges.

Consistent Heat Output: When it comes to making knives, high consistent heat is crucial. Gas forges are designed to deliver consistent temperatures, making it easier to heat treat and shape your blades.

Ease of Use: Gas forges are much easier to use than coal forges, which require you to stoke a fire throughout the forging process. With a gas forge, all you need is a fuel source and an adjustable regulator, and you’re good to go!

Fuel Efficiency: Gas forges have insulated walls that help keep the heat contained. This helps to reduce fuel consumption and makes them more cost-effective than coal. You also won’t have to bother with the hassle of moving and storing large amounts of coal.

Safety: Gas forges are much safer than traditional coal forges since there is no open flame or hot coals to worry about. You also don’t have to worry about smoke inhalation or sparks that can cause a fire.

These are just some of the benefits that make gas forges an ideal choice for knife making. With the right setup, you can easily create custom knives with professional results.

Frequently Asked Questions

What’s the best gas forge for knife making?

The best overall gas forge, in my opinion, is the “Mr Volcano Hero 2”. It has 2 burners and solid construction. The insulation distributes the heat very nicely for small to medium-sized knives. You’ll also be able to try your hands on Damascus steel with ease.

What’s the cheapest gas forge for knife making?

If you’re looking to get started with making knives and want a cheap gas forge that still works, the Hero 1 (also by Mr Volcano). It has a single burner that’s simple to use and very good insulation. I purchased mine when I first started blacksmithing and still use it 7 years later. It’s my go-to forge for small knives and basic projects.

How much fuel does a gas forge use?

The general rule of thumb is that a gas forge will consume about 1/2lb of fuel per hour for every burner you use. So if you have a two-burner forge, it will use about 1lb per hour. This will vary depending on your fuel source and the size of your project.

How long will a propane tank last forging knives?

A 20lb propane tank will typically last around 35-40 hours of forging while a 100lb tank will last up to 200 hours. Of course, this is only an estimate and will depend on how often you’re using your forge and the size of your projects.

Conclusion

Gas forges are a great choice for knife makers who want to achieve consistent and reliable heat output without having to worry about hot coals or an open flame.

Before selecting a forge, make sure to consider factors like portability, fuel efficiency, heating capacity, and heat distribution. Doing so will help you find the perfect gas forge for your needs and budget.

Once you have the right setup in place, you’ll be ready to start forging custom knives with professional results. Good luck!